WATERJET SPECIALISTS

Offering complete abrasive waterjet systems, job shop services, spare parts and repair services.

Contact Us

CUTTING SERVICES

Aquajet offers a number of cutting services to assist with your waterjet cutting needs.

Capabilities

WATERJET MACHINES

Partnering with TECHNI Waterjet has allowed us to offer the best of the best in cutting technology.

Machines

SPARE PARTS

Offering both OEM and aftermarket solutions we are guaranteed to have what you’re looking for. Call us today or shop online.

Shop

REPAIR SERVICES

With a staff of fully trained technicians we are ready to solve any issues that you may have. From training to repair, we’ve got you covered.

Contact Us

About AquaJet

Bloomfield, Connecticut

The power of water formed many of our great natural wonders and, thus, we have used it to better ourselves. Aquajet Cutting Technologies is a waterjet company formed as a division of Aerospace Alloys, Inc. to better fill the needs of our customers. Established in 1980 as the first waterjet house in the area, we have become a one-stop waterjet shop with a customer-centric attitude. We chose abrasive waterjet cutting, because it is the only method that allows us to cut virtually any material.

11 Britton Dr, Bloomfield, CT 06002

860.218.2061

CUTTING SERVICES

OUR IN-HOUSE WATERJET CUTTING CAPABILITIES

Aquajet Cutting Technology offers multiple waterjet cutting systems in-house to fulfill any part cutting needs that you may have. Our capabilities span from super accurate micro-waterjet cutting to the quick cutting capabilities of ultra-high pressures, and even 5-axis cutting! As an AS9100 and ISO 9001 quality certified company our commitment to you is to deliver you the best quality cut parts on time. Send us a message with your requirements and we’ll show you how our waterjets can cut through the competition!

Distributing Partners of the Best in Waterjet

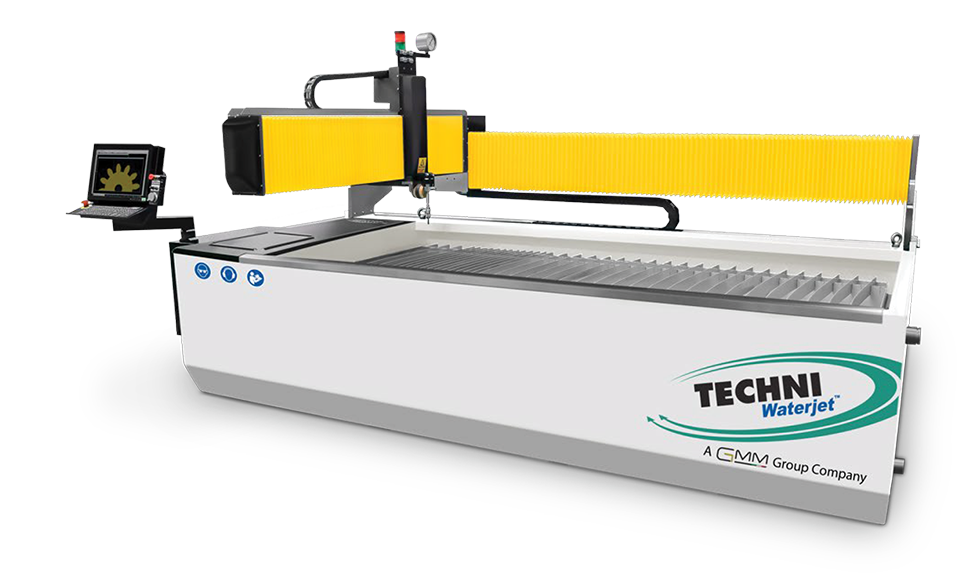

TECHNI WATERJET

HIGH PERFORMANCE CUTTING MACHINERY

TECHNI Waterjet is committed to offering waterjet cutting machines of the highest quality. The Techjet has been designed specifically for the very tough abrasive waterjet environment. It uses a minimum of moving parts, which have been manufactured from corrosion resistant materials. This ensures the Reliability of the Techjet machines for many years after their installation.

H2OJET

REPLACEMENT PARTS AND PUMPS

H2O Jet provides high pressure pumps and parts for waterjet cutting systems. Every part is meticulously engineered and rigorously tested. Our high performance, straightforward part designs ensure you get high-pressure water, when and where you need it. Our parts are field-tested and operator approved because they are designed to last longer, simplify maintenance, and improve the way you work. Our parts are compatible with many waterjet systems and can drive greater efficiencies and improvements across the board.

EBBCO

FILTRATION AND WATER RECYCLING

Ebbco Inc. specializes in waterjet filtration from the cutting tank and recycling of water that would normally be wasted during the cutting process. Their lineup includes Garnet Removal Systems, Closed Loop Systems and Chillers.