6 abrasive water-jet cutting machines

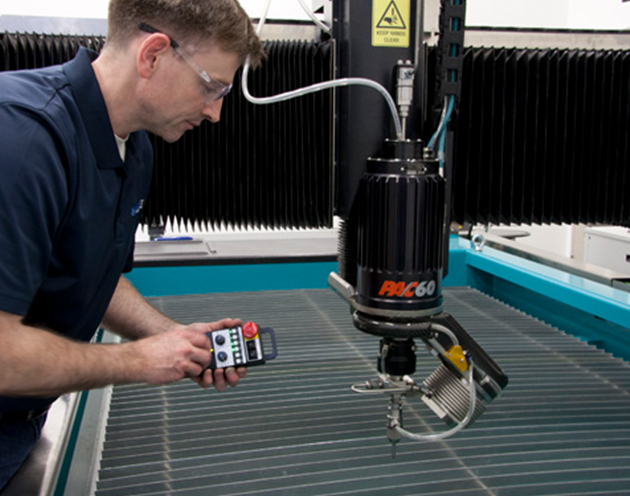

Aquajet Cutting technology has 6 abrasive water-jet cutting machines that can offer multiple head cutting as well as 5-axis cutting. Advantages of the water-jet cutting process include no HAZ (heat affected zones), therefore providing reduced machining costs and excellent edge quality while requiring minimum tooling.

We value your time and therefore offer prompt service, same day quotes, quick turnarounds and inspection services. We try to find solutions to your needs by providing technical support to our clients such as in-house CAD services and we try to increase your bottom line by maximizing material utilization through our nesting capabilities. We are also capable of using your .dxf files as a more economical way to serve your needs.

Tolerances on this machine can be as tight as +/-0.005. However this is dependent on the thickness of the material.